The astute reader can probably figure out what this is and what it's a test setup for:

Saturday, November 13, 2021

Thursday, November 11, 2021

Monday, October 11, 2021

Thursday, August 12, 2021

Espresso machine software testing

Testing a mostly-functional espresso machine gui. Somewhat Decent inspired. While I don't have an interface for creating espresso profiles from within the gui, I can write arbitrary espresso profiles/state machines in python which is pretty powerful. Testing with the Puck Simulator.

- Cycle water through the tank at 2 mL/s until the water and the group head get up to temperature (I cheated this in the video and turned off heater power)

- Flow water through the group head to the drip tray at 2 mL/s for 2 seconds to purge the air from the group.

- Block off the drip tray, flow to the group at 2 mL/s until the pressure reaches 6 bars.

- Run at a flat 6 bars until the shot weight (estimated from the pump speed/pressure/flow curve since I don't have a built-in scale yet) reaches 32 grams.

- Open the valve between the drip tray and group head to rapidly purge pressure (so it doesn't keep dripping)

- Reset to the beginning and wait for input.

Tuesday, August 3, 2021

Adjustable Puck Simulator

Sunday, July 11, 2021

Monday, July 5, 2021

Mill Enclosure

Last Sunday I whipped up an enclosure design for the mill to replace the shipping crate. It's entirely made from 2d laser cut panels (I used SendCutSend, introduced to me by Alex. A+ would use again) standard lengths of 3d-printer aluminum extrusion, and off the shelf hardware. I'll post CAD in case it's useful to anyone else with this mill once I've made any tweaks I need to:

Monday, June 28, 2021

Half way done

Thursday, June 3, 2021

The scrap pile grows....

Wednesday, May 19, 2021

Gratuitous simultaneous 5-axis

Tuesday, May 18, 2021

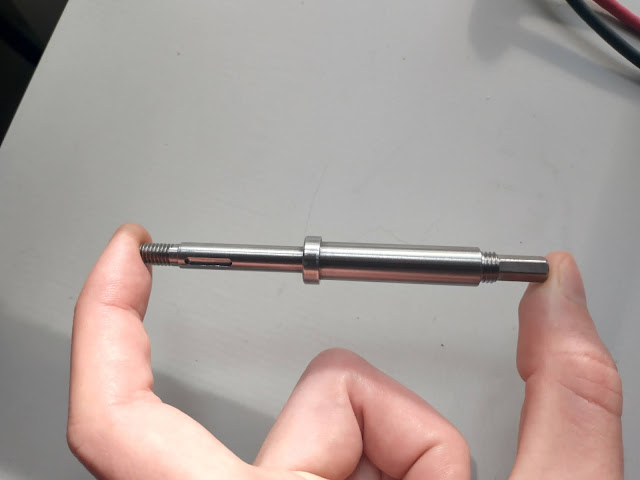

Stainless Shaft

Making a stainless shaft. Nothing super fancy, but it turned out pretty nice so here are some photos. Turned on the tiny lathe, threads/hex/keyway done on the mill

Sunday, May 2, 2021

Tuesday, April 6, 2021

Pressure control, 1 kHz USB data logging

Sunday, April 4, 2021

STM32 USB CDC + PyUSB Data Transfer

First experiments using native USB CDC (communications device class) on STM32's, using the CubeMX libraries:

It's been surprisingly straightforward to get working. I basically just followed this video from ST, with a few minor changes. I've been able to hit up to 650 kilobytes/s transfer (micro to computer) which seems to be the limit for the ST libraries. Put another way, I can log ~160 floats at 1 kHz. Although not nearly as fast as USB Full Speed can be, it's way faster than serial, it's non-blocking, has CRC error checking with auto-retry, variable packet size, and so on. Overall a very nice data transfer experience. It's great to not have to think about packet structure, accidentally being off by one byte, error checking, and all the other headaches that usually go along with serial.

The gif is a PyQt GUI using PyUSB for USB data transfer, using pyqtgraph for plotting, same as the dynamometer GUI. Plotting performance is a little disappointing. I get ~9 FPS plotting 19 traces at 2000 points/trace. Performance seems to scale linearly with number of traces, but not with number of points, which is kind of interesting - plotting 1/5 as many points only increases the frame rate by 50%.

Tuesday, March 23, 2021

Frequency response measurement

Sunday, February 21, 2021

Tuesday, February 16, 2021

Espresso Machine Group Head Machining

Wednesday, February 3, 2021

Monday, January 18, 2021

First attempt at shrink fit tool holders

The eventual goal is to have these for all my tools so I can preset tool lengths and never swap ER collets. This one was machined on a kind of sketchy lathe at work, so that's my excuse for the .0005" runout. In the future I'll bore them out in the mill spindle.

Sunday, January 10, 2021

Pretending the mill is a lathe

A quick experiment in doing some turning on the mill. The mill is in "TCP" mode, so I can jog it in work coordinate system rather than machine coordinate system, and turn a taper by jogging in the WCS Z axis. Material is 17-4 PH stainless, 5000 RPM, .3mm DOC.

Thursday, January 7, 2021

Thin Part Fixturing

Using the super glue and blue tape trick to fixture some large (relative to the mill), thin parts. I normally used double-sided tape for stuff like this, but didn't have any on hand.

Tape applied to stock and fixture: