|

| 3D printed expanding fixture for op 2 |

It has been an eventful year. I'm finally back to working on projects.

After some firmware fiddling, the new drive units are finally spinning, driven by the kart's original gen 2 Prius-based inverter:

Finally retrieved it from MITERS, where it's been hanging from the ceiling for the last six years or so

|

| Missing a rotor |

Machining a new shaft for the rotor:

|

| Improvised chip deflector for roughing |

|

| nice |

|

| Other side done |

|

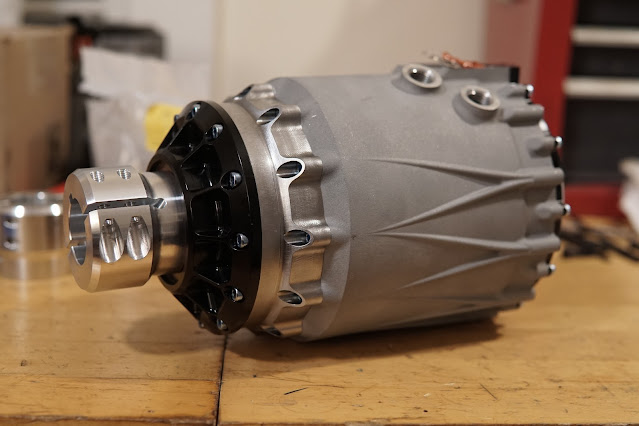

| bearing and lock ring test fit |

|

| Next to the stock shaft. Going for a normal press vs the straight knurl on the stock shaft. |

|

| I don't own a 2d printer and didn't plan far enough ahead to print the drawing at work, so this happened |